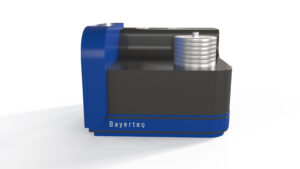

Carbon Black Tester

The Bayerteq Nabertherm carbon black tester consists of an aluminium frame combined with a high class oven to be configured dependant on standard choice. Tests may be performed for the determination of the carbon black content of thermoplastic materials, such as: polyethylene, polypropylene and polybutene. The carbon black content is determined by means of weight difference. The Carbon Black equipment comprises the electric tube furnace and a side panel. The front panel of the electric tube furnace displays the controls needed to operate the furnace and automatic temperature control. The electric tube furnace is for heating the combustion pipe in which the shuttle is inserted with the sample to be tested. The purpose of the side panel is to support the outside components, namely: the flow meter, the flow control valve, the washing bottle and the drying tube. The Carbon Black equipment has been designed and made according to the requirements of the standards: ASTM D1603 and ISO 6964 and serves to determine the carbon black content of thermoplastic materials, such as polyethylene, polypropylene and polybutene. The carbon black content of the material examined is carried out gravimetrically after pyrolysis in nitrogen stream. The method of determination indicated by standards consists in calculating the difference in weight of the sample before and after treatment in the equipment. This method is not applicable to materials that contain non volatile pigments or inorganic. The Carbon Black complies with the standards ASTM D 1603 and ISO 6964.

A sample of known weight is placed into a weighed combustion boat. The sample is then placed into a 600°C tube furnace under a dry oxygen free Nitrogen purge. After a set time the combustion boat with the burn residue is cooled under the nitrogen purge and weighed. The combustion boat is then placed into a 600°C muffle furnace to oxidize the carbon residue. When the carbon is completely oxidized the combustion boat is cooled and weighed.

Specifications:

- Specimen size: one to a few grams.

- Tube furnace: 600°C

- Oven casing: Stainless steel

- Frame: Aluminium

- Temperature range: Up to 1200°C

- Temperature control: Programmable LCD display, more language possible

- Dimensions: 550 x 435 x 880mm (L x W x H)

- Weight: 62 kg.

- Electrical supply: 230 V

- Dimensions: Oven 434x340x510mm (LxWxH)

- Weight: 25 kg.

Controller: Programmable LCD display, easy-to-navigate menu configuration and the clear display design. Various menu languages can be selected for plain text information. By default, a USB interface is integrated for process documentation and to archive programs and settings.

Working tubes: Working tube of C 530 ceramic including two fiber plugs as standard equipment. Tube length 450 mm, Heated length 250mm. Length Constant temp. +/- 5 K: 80 mm3

Standards: Complying with ASTM D1603.

Gas supply Gas supply system for non-flammable protective or reactive gas with shutoff valve and flow meter with regulator valve, piped and ready to connect

Accessories: Supplied with combustion tube, nozzles, porcelain sample cups, glass traps, U shaped drying tube for dessicant, flow meter, flow regulator, set of hose to connect furnace and the other parts. As described in ASTM D1603 fig. 1 Assembly of apparatus. Manual gassing system. Please note that Nitrogen gas cylinder is not part of the supply and should be sourced locally